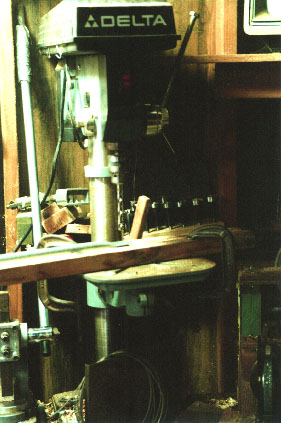

A drill press makes the drilling job a lot safer and easier.

The jig is a 2x4 with a V about 3/4 inch deep cut

into it lengthwise. I used a tablesaw, but if you don't

have an easy way to make the cut, you can build up a channel

by using two lengths of quarter-round moulding or even

just two long strips of wood set just far enough apart so

the conduit nestles securely between them.

It is important to clamp the jig is clamped to the

drill-press table so you can drill holes in exactly the

same position for struts of the same length.

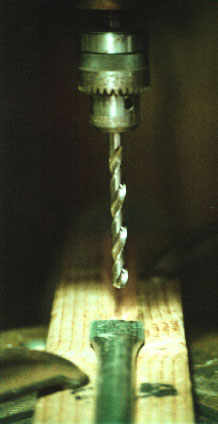

Be sure that the drill is aligned exactly over the center

and at the correct distance from the end of the strut.

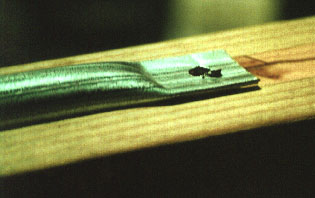

Drilling the struts produces a lot of metal shavings.

These are razor sharp and get stuck to your shoes, in

your fingers, etc. Blow these away or use a brush.

Don't brush them away with your fingers or you'll get

nasty metal slivers.

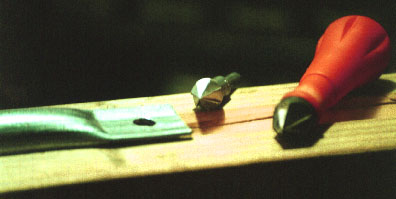

After drilling the strut and brushing away the metal

shavings there will be some excess material around the

hole (usually on the underside). This material is a

result of the drilling process and is called flash.

You must remove the flash or it will interfere with assembly

and will probably cut someone badly when they grab a

strut by its end.

You can use a special chamfer bit in a hand drill

or drill press, or use a hand chamfering tool.

Removing the flash is pretty easy with one of these tools.

Previous  Next Next |